The Ordinary Element That Built Our Extraordinary World: A Guide to Silicon

Explore the fascinating world of silicon. Learn what it is, how it’s used in everything from computer chips to solar panels, and discover the UK’s own ‘Silicon Fen’.

This post may contain affiliate links. If you make a purchase through these links, we may earn a commission at no additional cost to you.

Right now, you’re probably holding it, wearing it, or sitting near it. It’s in the device you’re using to read this, in the windows of your house, and even mixed into the concrete of the pavement outside. It’s an element so common it makes up over a quarter of the Earth’s crust, second only to oxygen. We’re talking about silicon, a humble substance that has quietly become the backbone of modern life.

You might hear the word and immediately think of Silicon Valley in California, the global hub of tech innovation. But its story is much bigger and closer to home than you might imagine. From the sandy beaches of Cornwall to the high-tech laboratories in Cambridge, known as ‘Silicon Fen’, this remarkable element has shaped Britain and the world in countless ways.

So, what is silicon? At its heart, it’s a natural element, like oxygen or iron, with the chemical symbol Si and atomic number 14. But calling it just another element is like calling The Beatles just another band. It’s a master of disguise. In nature, you’ll rarely find it on its own. Instead, it loves to team up with oxygen to form silica, the main ingredient in sand and quartz. Bond it with other elements, and you get a vast family of materials called silicates, which make up about 90% of the Earth’s crust. Think of granite, clay, and mica—all part of the silicon family.

But the real magic happens when we purify it. In its ultra-pure form, silicon becomes a semiconductor. This means it can be precisely controlled to either conduct electricity or block it. It’s this unique property that makes it the perfect material for creating the tiny electronic switches, called transistors, that power every single computer chip. Without silicon, there would be no smartphones, no laptops, no internet, and no space travel.

This article is your guide to this incredible element. We’ll dig into its history, explore how a Swedish chemist first pinned it down, and see how it went from a simple curiosity to the most important material of the 21st century. We’ll journey from the geology beneath our feet to the technological marvels it enables, and we’ll uncover the UK’s own significant role in the silicon story. Let’s get started.

What Exactly is Silicon? The Building Block of Modernity

To really get to grips with silicon, we need to look at it from a few different angles—what it is chemically, where it comes from, and what makes it so special. Think of it like getting to know a person: you need to understand their personality, their background, and what they’re good at.

The Chemistry of Silicon: A Friendly All-Rounder

On the famous Periodic Table, which is like a big chart of all the known elements, silicon sits in group 14. This places it in the same family as carbon, the element that forms the basis of all life on Earth. This family connection is a big clue to silicon’s versatility. Like carbon, it can form strong, stable bonds with four other atoms at once. This ability makes it fantastic at building large, complex structures.

But while carbon is the star of the biological world (forming everything from wood to DNA), silicon is the undisputed king of the mineral world. In its natural state, it’s a metalloid, which means it has properties of both metals and non-metals. It’s brittle, has a metallic shine, and is a solid at room temperature.

The most important thing to know about silicon is its relationship with oxygen. They’re like best mates who are almost always found together. The compound they form, silicon dioxide (SiO₂), is more commonly known as silica. This is the stuff that makes up sand and the beautiful, six-sided crystals of quartz. When you’re walking on a sandy beach, you’re walking on countless tiny grains of silicon dioxide.

From Sand to Chip: The Journey to Purity

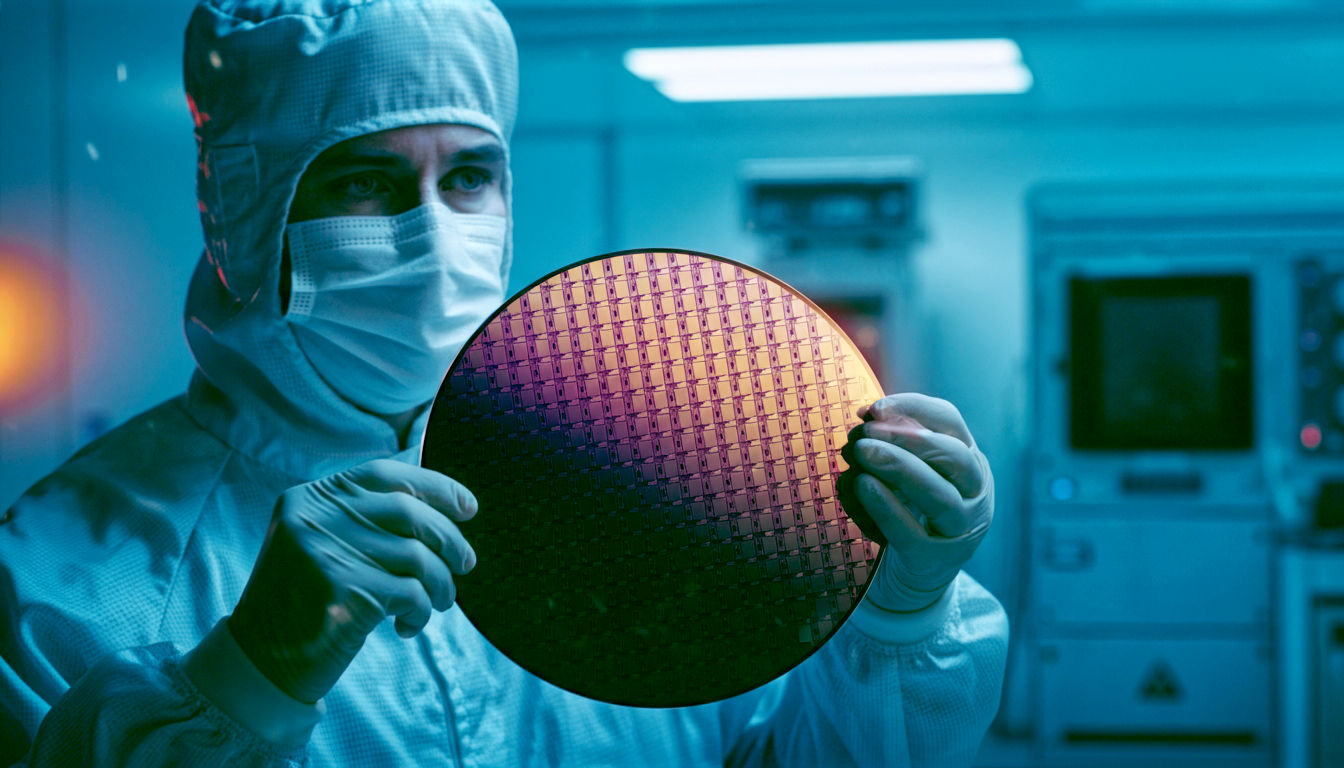

The silicon used in electronics is very different from the silicon found in sand. To become useful for technology, it needs to be purified to an incredible degree. We’re talking about 99.9999999% purity, a level known as “nine-nines” purity. At this level, there’s only one foreign atom for every billion silicon atoms.

How do we achieve this? The process is a bit like a high-tech version of smelting.

- Start with the raw material: It begins with high-purity quartz sand (silicon dioxide).

- Heat it up: The sand is heated to scorching temperatures of around 2000°C in a furnace with carbon. The carbon grabs the oxygen atoms, leaving behind molten silicon. This gets you to about 99% purity, which is known as metallurgical-grade silicon. It’s used to make alloys like aluminium-silicon for car parts, but it’s not nearly pure enough for electronics.

- The final purification: To get to electronic-grade silicon, it undergoes a complex chemical process, often the Siemens process. The silicon is converted into a gas, which is then passed over heated silicon rods. The pure silicon deposits onto the rods, growing into large, grey, sausage-shaped cylinders called ingots. This process leaves almost all impurities behind.

These ingots are the starting point for every computer chip in the world. They are sliced into incredibly thin, perfectly circular discs called wafers, which are then polished until they are smoother than a mirror. It’s on these wafers that the microscopic world of circuits and transistors is built.

The Semiconductor Secret: Why Silicon is Perfect for Electronics

So, why go to all this trouble? Because pure silicon is a natural semiconductor. This is its superpower.

- Conductors, like copper, let electricity flow through them easily.

- Insulators, like rubber, block electricity completely.

- Semiconductors are the clever ones in the middle. They can act as either a conductor or an insulator, depending on the conditions.

On its own, pure silicon is actually a pretty poor conductor. But we can change its behaviour by adding tiny, carefully controlled amounts of other elements. This process is called doping.

Imagine a crowded ballroom where all the dancers (electrons) are paired up and can’t move. That’s like pure silicon—no free electrons to carry a current.

- If we ‘dope’ it by adding a tiny bit of phosphorus, which has one extra electron, we introduce a few lone dancers into the ballroom. These free electrons can now move around and carry an electrical current. This is called n-type (negative) silicon.

- If we ‘dope’ it with boron, which has one less electron, we create a few “gaps” in the dance floor where a dancer should be. These gaps, or holes, can also move around as electrons jump in to fill them. This is like a positive charge moving, so it’s called p-type (positive) silicon.

By creating tiny regions of n-type and p-type silicon right next to each other on a wafer, engineers can build microscopic switches—transistors. A transistor can be turned on (allowing current to flow) or off (blocking it) with a tiny electrical signal. These on/off states represent the 1s and 0s of binary code, the fundamental language of all computers.

A modern processor, like the one in your phone, contains billions of these silicon transistors, all working together at incredible speeds. It’s this simple, controllable property of doped silicon that makes all of our digital technology possible.

The Story of Silicon: From a Chemist’s Bench to Global Dominance

The journey of silicon from an unknown substance to the cornerstone of our age is a tale of scientific curiosity, relentless innovation, and a bit of happy accident. It wasn’t discovered overnight; it took decades of work by some of Europe’s greatest chemists to finally isolate and understand it.

Pinning It Down: The Discovery of a New Element

In the late 18th and early 19th centuries, chemists were in a frenzy of discovery, identifying new elements left, right, and centre. One of the great puzzles was the nature of common materials like sand, quartz, and glass. Scientists suspected they contained a new, undiscovered element, but it was proving fiendishly difficult to separate.

The French chemist Antoine Lavoisier, known as the “father of modern chemistry,” first proposed in 1787 that silica was the oxide of a new element. Several chemists tried to isolate it, including the celebrated Cornish inventor Sir Humphry Davy. In 1808, Davy was on a roll, having already discovered elements like sodium and potassium. He tried to break down silica using his powerful new tool, the electric battery, but failed. He was convinced the element existed, and he even gave it a name: “silicium,” from the Latin silex, meaning ‘flint’. The ‘-ium’ ending was common for metals, and Davy suspected it would be one.

The breakthrough finally came in 1824, thanks to the meticulous work of the Swedish chemist Jöns Jacob Berzelius. Berzelius was a giant of 19th-century science, credited with discovering several elements and creating the modern system of chemical notation (the symbols like H for hydrogen and O for oxygen). He succeeded where others had failed by heating potassium with a silicon compound in a sealed tube, which stripped the oxygen away. He produced a brown powder of amorphous silicon—the first time the element had been seen in its pure, albeit non-crystalline, form.

For his achievement, Berzelius is widely credited as the discoverer of silicon. The name was later changed slightly in English. In 1831, the Scottish chemist Thomas Thomson decided “silicium” sounded too much like a metal. Since the new element had properties more like carbon and boron, he changed the name to silicon, which has stuck ever since.

The Quiet Years: A Solution Looking for a Problem

For the next century, silicon remained little more than a laboratory curiosity. It was interesting to scientists, but it didn’t seem to have any practical use. Its main application was in steel production, where adding a small amount of silicon made the steel stronger. But the electronics revolution was still a long way off.

The first hint of silicon’s electronic potential came in the early 20th century with the invention of the “cat’s-whisker detector.” This was a key component in early crystal radio sets, those amazing devices that allowed people to listen to broadcasts without any batteries or power. The detector used a fine wire (the “whisker”) touching a crystal of a semiconducting material, often galena or carborundum (silicon carbide). The point contact acted as a crude diode, allowing the radio signal to be converted into sound. It was an early, clumsy glimpse into the world of semiconductors, but the science wasn’t yet understood.

The Transistor and the Birth of the Silicon Age

The true silicon revolution began after World War II, at a legendary American research lab called Bell Labs. In December 1947, three physicists—John Bardeen, Walter Brattain, and William Shockley—invented the first working transistor. Their device was a clunky thing made of germanium, another semiconductor. But it could do something amazing: it could amplify an electrical signal and act as a switch, just like the bulky, hot, and unreliable vacuum tubes used in early computers. For this, they won the Nobel Prize in Physics in 1956.

At first, germanium was the material of choice. But it had problems. It was unstable at higher temperatures and harder to work with. Attention soon turned to silicon. It was far more abundant (making it cheaper), much more stable, and when it reacted with air, it formed a perfect, insulating layer of silicon dioxide. This protective layer was a game-changer. It made it possible to build robust, reliable transistors on a flat surface.

The final piece of the puzzle fell into place in the late 1950s. At Texas Instruments, Jack Kilby created the first integrated circuit in 1958, putting several components onto a single piece of germanium. A few months later, at Fairchild Semiconductor, Robert Noyce developed a much more practical version using silicon. Noyce’s design, which used a flat silicon wafer and printed the circuit components onto it, was the one that truly launched the microchip industry.

This was the moment the Silicon Age truly began. Companies like Fairchild and Intel (co-founded by Noyce) in an area south of San Francisco started producing silicon chips in vast numbers. The region quickly became known as Silicon Valley, and the world was never the same again.

Silicon in Our Lives: More Than Just Chips

While silicon’s starring role is in the world of electronics, its influence extends into almost every corner of our lives. From the house we live in to the products we use every day, silicon compounds are the unsung heroes working behind the scenes. They are incredibly versatile, appearing in forms ranging from hard-wearing ceramics to flexible, rubbery plastics.

The World of Silicones: The Flexible Family

Don’t confuse silicon the element with silicones. Silicones are a huge family of synthetic polymers, which are long, chain-like molecules. They have a backbone made of repeating silicon-oxygen links, with other organic groups attached. This unique structure gives them a fantastic range of properties. They can be oils, gels, rubbers, or hard resins.

You’ll find silicones everywhere:

- In the kitchen: Silicone bakeware is a modern marvel. It’s flexible, non-stick, and can handle high temperatures without melting. Spatulas, oven mitts, and ice cube trays are often made of silicone.

- In the bathroom: Many shampoos, conditioners, and skin creams contain silicones like dimethicone. They make hair feel smooth and silky and help skin products spread evenly. They’re also used in deodorants and antiperspirants.

- Around the house: Silicone sealant is the waterproof, flexible gunk used to seal the edges of bathtubs, sinks, and window frames. It’s brilliant because it stays flexible and doesn’t crack over time.

- In medicine: Because silicones are biocompatible (meaning the human body generally doesn’t react to them), they are used in all sorts of medical devices, including tubing, contact lenses, and medical implants.

- In industry: Silicones are used as lubricants, adhesives, and coatings. Their ability to repel water makes them great for waterproofing fabrics and protecting buildings.

Glass, Ceramics, and Cement: The Hard Workers

Long before the invention of the microchip, humans were using silicon compounds to build their world. The oldest and most obvious example is glass.

Glass is made by melting sand (silicon dioxide) at very high temperatures and then cooling it quickly. By adding other substances, we can change its properties. For example, adding boron creates borosilicate glass (like Pyrex), which can withstand sudden temperature changes without shattering. Adding lead makes sparkling lead crystal.

Ceramics are another ancient technology based on silicon. Bricks, pottery, tiles, and porcelain are all made from clay, which is largely composed of silicate minerals. When fired in a kiln, these minerals fuse together to create hard, durable, and heat-resistant materials. Modern advanced ceramics, like silicon nitride and silicon carbide, are so tough they are used in everything from armour plating to components for jet engines.

And we can’t forget cement. The most common type, Portland cement, is the key ingredient in concrete, the most widely used building material on Earth. It’s made by heating limestone and clay (which is full of silicates) in a kiln. The resulting powder, when mixed with water, sand, and gravel, hardens into the solid, artificial rock that forms our roads, bridges, and buildings.

In Solar Panels: Capturing the Sun’s Energy

Silicon’s semiconductor properties aren’t just for computing; they’re also essential for renewable energy. Most of the solar panels you see on rooftops are made from silicon. These are known as photovoltaic (PV) cells.

Here’s how they work, in a nutshell:

- A solar cell is made of two layers of doped silicon, one n-type and one p-type, sandwiched together.

- When sunlight (which is made of tiny particles of energy called photons) hits the silicon, it knocks electrons loose.

- The built-in electric field at the junction between the n-type and p-type layers forces these loose electrons to flow in one direction.

- This flow of electrons is an electric current! Metal contacts on the cell collect this current, which can then be used to power our homes.

About 95% of the world’s solar panels are silicon-based. It’s a technology that is constantly improving, becoming more efficient and cheaper every year. It’s a clean, green application of silicon that is helping us tackle climate change.

A Surprising Role in Nature

Silicon is also surprisingly important in the biological world, although not as central as carbon. Some living things use silica to build their structures. The most famous are diatoms, which are tiny, single-celled algae that live in oceans and lakes. They build intricate, beautiful shells out of glass (silica). When they die, their shells sink to the seabed, forming thick deposits of diatomaceous earth, a soft, crumbly rock that’s used in everything from filtration to natural insecticides.

Some plants, like horsetails and bamboo, also absorb silicon from the soil and use it to strengthen their stems. It’s even present in our own bodies, in small amounts, where it helps to keep our bones, hair, and skin healthy.

Silicon’s British Connection: From Fenland to the Future

While the name “Silicon Valley” points to California, the United Kingdom has its own powerful and influential hub of silicon innovation. It’s a story of academic brilliance, entrepreneurial spirit, and a unique ecosystem that has produced some of the world’s most successful tech companies.

Silicon Fen: The UK’s Answer to Silicon Valley

In the flat, misty landscape of Cambridgeshire, surrounding the ancient university city, lies Silicon Fen. The name, a playful nod to both its American counterpart and the local marshy geography, describes one of Europe’s most important technology clusters. It’s not a single place but a collection of high-tech companies, start-ups, and research labs scattered in and around Cambridge.

The story of Silicon Fen began in the 1970s. The key ingredient was Cambridge University, with its long history of groundbreaking science and engineering. A crucial step was the university’s decision to establish the Cambridge Science Park in 1970, the first of its kind in the UK. This gave academics and entrepreneurs a place to turn their brilliant ideas into commercial products.

One of the first major successes was Acorn Computers. Founded in Cambridge in 1978, Acorn was at the heart of the British home computer boom of the 1980s. Their most famous creation was the BBC Micro, a sturdy and reliable machine that was placed in almost every school in Britain. An entire generation of British children, including many who would go on to become leading programmers and tech entrepreneurs, learned to code on a BBC Micro. It was a pivotal moment that helped foster a culture of digital literacy in the UK.

The ARM Revolution: A British Design in Every Pocket

Acorn’s greatest legacy, however, was a spin-off company that would go on to conquer the world. In the mid-1980s, Acorn’s engineers were designing a new, powerful, and efficient processor for their next generation of computers. They came up with a revolutionary design based on a RISC (Reduced Instruction Set Computing) architecture. It was simpler, used far less power, and was cheaper to make than the complex processors being built by giants like Intel.

In 1990, this processor division was spun out to form a new company: Advanced RISC Machines, or ARM. The company had a clever business model. Instead of making and selling chips themselves, they licensed their processor designs to other companies, who could then use them to build their own custom chips.

It was a masterstroke. The timing was perfect. In the 1990s and 2000s, the world was going mobile. Companies like Nokia and, later, Apple needed processors for their new mobile phones and smartphones that were both powerful and incredibly energy-efficient to give a long battery life. ARM’s designs were the perfect fit.

Today, ARM-based processors are the most widely used in the world. They are in over 95% of smartphones, including every iPhone and the vast majority of Android devices. They’re in tablets, digital cameras, smart TVs, and the growing number of ‘Internet of Things’ devices. A small company born out of the BBC Micro project in Cambridge created the silicon brain that now powers the mobile world. It is arguably Britain’s greatest technology success story.

Beyond the Fen: The UK’s Broader Silicon Industry

While Silicon Fen is the most famous cluster, the UK’s silicon and semiconductor industry is spread across the country. There are other important hubs, particularly in South Wales (dubbed “Silicon Glen” in Scotland in its heyday, though less prominent now) and in cities like Bristol and Southampton.

The UK has particular strengths in certain areas:

- Compound Semiconductors: While most chips are made from pure silicon, mixing silicon with other elements like germanium (silicon-germanium) or creating chips from other compounds (like gallium arsenide) can produce devices that are faster or operate at higher frequencies. The UK, particularly the cluster in South Wales, is a world leader in this specialised field.

- Chip Design: The UK’s real strength lies not in manufacturing the chips (which is incredibly expensive and dominated by Asian companies), but in designing them. Like ARM, many British companies are “fabless,” meaning they design the chips but outsource the manufacturing.

- Research and Development: With world-class universities and research institutions, the UK remains at the forefront of semiconductor research, exploring new materials like graphene and new concepts like quantum computing that could one day replace silicon.

The British government has recognised the strategic importance of this industry. In 2023, it launched the National Semiconductor Strategy, a plan to invest in the UK’s strengths in design and compound semiconductors, ensuring the country remains a key player in this vital global industry.

The Future of Silicon: Pushing the Limits

For over half a century, the story of the silicon chip has been one of relentless progress, famously described by Moore’s Law. In 1965, Intel co-founder Gordon Moore observed that the number of transistors that could be squeezed onto a microchip seemed to double approximately every two years. This incredible shrinking act has been the engine of the digital revolution, making our devices exponentially more powerful and cheaper.

But today, Moore’s Law is running out of steam. We are approaching the fundamental physical limits of silicon. Transistors are now so tiny—just a few atoms across—that quantum effects are starting to interfere with their operation. It’s getting harder and harder to keep the doubling trend going.

So, what’s next? Is the Silicon Age coming to an end? Not exactly. The future is likely to be a mix of clever new ways to use silicon and the gradual introduction of new materials and technologies to work alongside it.

More than Moore: Smarter Silicon Chips

The industry is now focused on a concept called “More than Moore.” If we can’t just keep cramming more transistors on a single chip, maybe we can get more performance by being smarter with our designs. This involves several exciting approaches:

- 3D Chip Stacking: Instead of building circuits on a flat 2D wafer, companies are starting to stack layers of silicon on top of each other and connect them vertically. This “chiplet” or 3D integration approach allows for shorter, faster connections and more power in a smaller space.

- Specialised Chips: Rather than having one processor do everything, we are seeing a rise in specialised chips designed for specific tasks. For example, Graphics Processing Units (GPUs), originally for gaming, are now essential for artificial intelligence (AI). Tensor Processing Units (TPUs) are custom-built by Google specifically for AI calculations. This specialisation makes computing far more efficient.

- Silicon Photonics: This is a truly futuristic idea. Instead of using electrons to move data around on a chip, silicon photonics uses photons—particles of light. Data can be transmitted at the speed of light using tiny, built-in lasers and waveguides etched onto the silicon. This could lead to a massive leap in computing speed and energy efficiency.

Life Beyond Silicon: New Materials on the Horizon

Scientists are also racing to find the materials that will eventually supplement or replace silicon in certain applications. There are several exciting candidates:

- Graphene: Discovered at the University of Manchester in 2004 (a Nobel Prize-winning achievement), graphene is a single layer of carbon atoms arranged in a honeycomb lattice. It’s incredibly strong, lightweight, and a phenomenal conductor of electricity. While creating graphene-based transistors has proven tricky, it has huge potential for next-generation electronics.

- Compound Semiconductors: As we saw with the UK industry, materials like gallium nitride (GaN) and silicon carbide (SiC) are already starting to replace silicon in high-power applications. They are more efficient and can handle higher voltages and temperatures. You’ll find them in the power adapters for new laptops and in the electronics for electric vehicles.

- Quantum Computing: This is the ultimate leap. Quantum computers don’t use transistors and binary bits (0s and 1s). Instead, they use the weird and wonderful principles of quantum mechanics, using qubits that can be a 0, a 1, or both at the same time. While still in its early days, quantum computing promises to solve certain types of problems that are impossible for even the most powerful silicon-based supercomputers.

The Enduring Legacy

Even as these new technologies emerge, silicon won’t be disappearing anytime soon. The global infrastructure for designing and manufacturing silicon chips is so vast and so refined that it will remain the workhorse of the electronics industry for decades to come.

The story of silicon is a perfect example of how science and engineering can transform our world. It started as a humble element, locked away in sand and rock. Through human ingenuity, we learned how to purify it, understand its unique properties, and shape it into the brains of the machines that define our modern era.

From the phone in your pocket to the vast data centres that power the internet, from the solar panels on our roofs to the medical devices that save lives, this ordinary element has enabled the extraordinary. It’s a reminder that sometimes, the greatest potential lies hidden in the most common of places, waiting for us to unlock it.

Further Reading

For those who wish to delve deeper into the world of silicon, semiconductors, and the history of technology, these resources are highly recommended:

- The Royal Society of Chemistry’s Periodic Table: An authoritative and accessible resource for detailed chemical information about silicon.

- Computer History Museum: An excellent resource for understanding the invention of the transistor and the integrated circuit.

- ARM Holdings (Corporate History): For insights into the story of one of the UK’s most successful technology companies.

- The Centre for Computing History, Cambridge: A UK-based museum with fantastic exhibits on the Acorn BBC Micro and the rise of British computing.